Lux Laboratory

Calibration

Services

Lux Laboratory can provide all your service needs, from calibration and repair to the supply of spare parts for different types of test equipment.

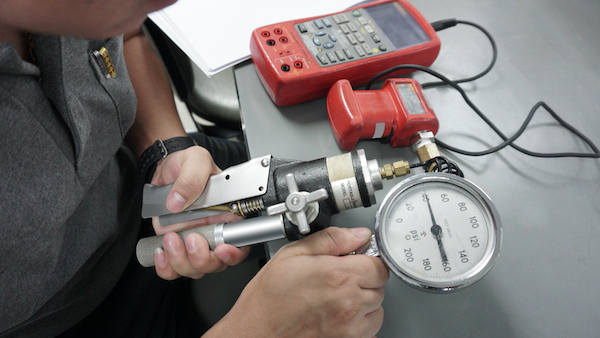

Pressure Measuring Instruments

Pressure gauge, transducer and transmitter

Direct current and low frequency measurements

Ammeter, ohmmeter, voltmeter

Temperature and humidity

Thermometer (LiGT , dial, digital) and hygrometer

Length measurement instruments

Mass and Related Measurement – Volume flow rate

Air flow meter, air velocity meter

To request the Calibration service for other equipment, please contact us .

Service and Support

Support the IoT Sensor Company, IAQ Sensor Company to manufacture their own product. To provide a professional suggestion to these companies.

Standard Calibration Service

(Estimated completion time: 7 – 10 working days)

Our calibration process can be completed within 7 – 10 working days for items within our scope. Compared with other service providers who require around 14 working days for calibration, we charge a regular calibration fee but with a shorter lead time.

Priority Calibration Service

(Expected completion time: 3 – 5 working days)

Priority calibration services are also available, subject to special requests. Clients can thus benefit from efficient calibration services.

on-site calibration services

within a few hours, returning to service within minutes

We also offer on-site calibration services to reduce downtime and carriage costs. Your equipment will be calibrated by our technicians at your site.

In traditional calibrations, instruments are packed, delivered to a laboratory, unpacked, calibrated, repacked then returned after several days or even weeks. Unfortunately, many clients lose production or testing capacity with the absence of essential test equipment on site.

With on-site calibration, devices can be calibrated in situ, allowing minimal downtime for production lines, testing, and engineering service operations. Equipment can be calibrated within a few hours, returning to service within minutes. In addition to reducing delivery costs and the risk of damage, on-site calibration can also save clients’ money when transporting calibration materials to and from calibration laboratories and their facilities.

- Mass and Related Measurement (HOKLAS Accreditation)

Pressure gauge calibration is crucial for ensuring the accuracy and reliability of pressure measurements in various industrial applications. Accurate pressure measurement is essential for maintaining product quality, ensuring safety, optimizing processes, and protecting the environment. Our pressure gauge calibrators allow for the rapid and precise calibration of different pressure ranges and media.

Regular pressure gauge calibration guarantees that the equipment operates at peak performance and helps identify potential issues before they cause significant problems, such as equipment malfunction or process failures.

- Electrical Calibration services

This discipline refers to the process of verifying the performance of, or adjusting, any instrument that measures or tests electrical parameters. Examples include direct current and low frequency electrical metrology. Principal parameters are voltage, current, resistance, inductance, capacitance, time and frequency.

We have developed an array of in-house method to evaluate the performance of precision measurement devices such as digital multimeters, ammeter, clamp meter, ohmmeter, and voltmeter.

Ammeter, ohmmeter, voltmeter

- Temperature and humidity Calibration Services

Places such as laboratory and cold chain are sensitive to temperature and relative humidity. Regular calibration of temperature and humidity monitoring devices can help to reflect the actual ambient environment and help to check if the system is functioning properly.

Thermometer (LiGT , dial, digital) and hygrometer

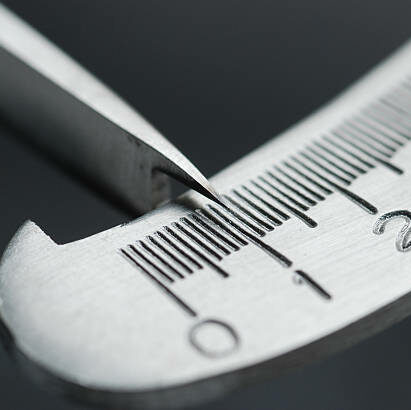

- Dimensional Calibration Services

Dimensional calibrations involve equipment that measures the physical size of an object related to length, width, diameters and angles. Dimensional equipment includes micrometers, calipers, ring gages and gage blocks.